At MultiMax Engineering Works, reliability is more than just a word—it is a guiding principle behind every decision we make. Our core value of reliability in product performance and on-time delivery shapes every aspect of our business operations.

We firmly believe that true reliability comes from long-term thinking. Whether we are investing in new production machinery, selecting high-quality raw material suppliers, or putting in extra hours to meet project deadlines, every decision is made with the goal of becoming a stable, dependable and trusted business partner for our customers.

This commitment to reliability is deeply embedded in our company culture and drives our teams to prioritize consistent quality, operational stability, and customer satisfaction above all else.

Our unwavering focus on reliability is clearly reflected in our key performance indicators:

By continuously improving our systems, processes and supply chain, MultiMax ensures customers receive not only high-performing products but also the peace of mind that comes from working with a dependable partner.

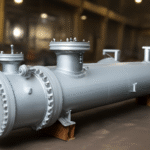

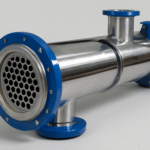

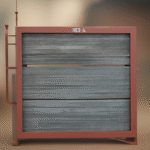

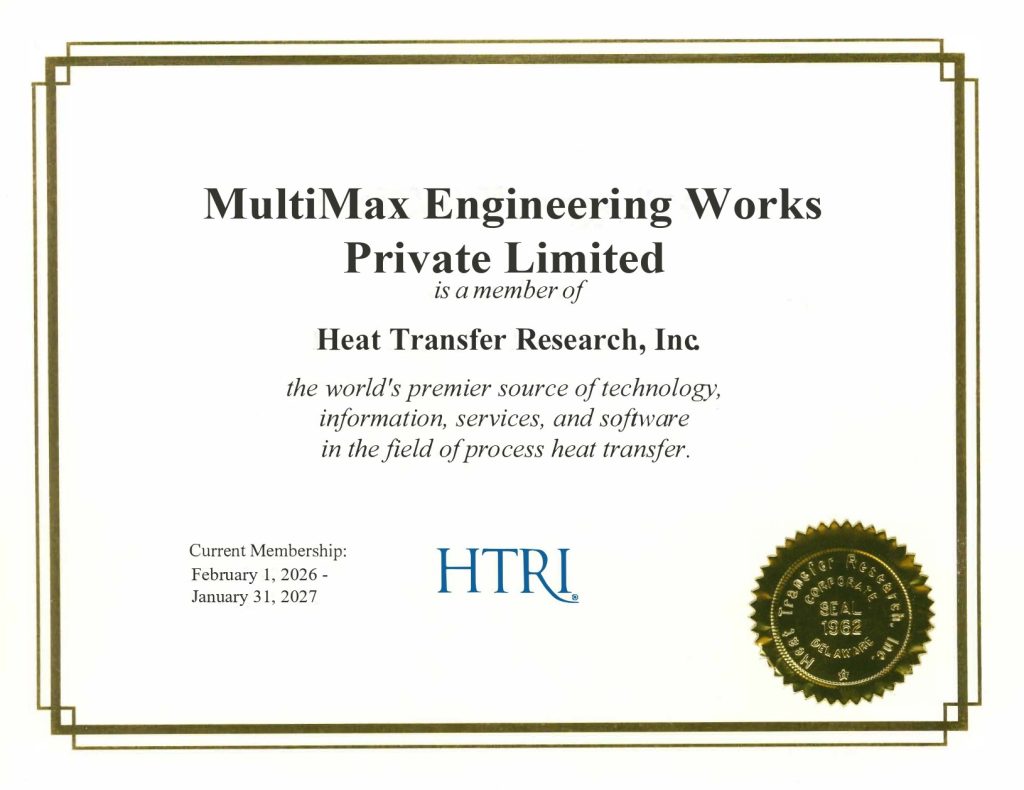

Multimax Engineering Works Pvt. Ltd. is proud to be a member of Heat Transfer Research, Inc. (HTRI) — the world’s leading consortium for process heat transfer research and heat exchanger technology. HTRI is a globally respected organization that advances engineering standards, cutting-edge research, and best-in-class software tools used by heat transfer engineers around the world. As an HTRI member, Multimax leverages advanced heat transfer research, industry-proven design software, expert technical support, and global best practices—strengthening our commitment to delivering world-class, reliable heat exchanger solutions across oil & gas, power, petrochemical, and process industries.

At MultiMax Engineering Works, Excellence in Manufacturing is more than a goal—it is a continuous journey driven by lean thinking, advanced infrastructure and a culture of improvement on the shop floor.

We have successfully integrated Lean Manufacturing tools to optimize production processes and reduce product manufacturing costs. Techniques like Poka-Yoke (error-proofing), Kaizen (continuous improvement), daily Gemba walks and 5S audits are deeply ingrained into our daily operations, encouraging employees at all levels to identify and eliminate waste. One of the most impactful changes has been the transition from traditional batch production to Single Cell Continuous Flow manufacturing, significantly improving shop floor efficiency, reducing lead times and enhancing product quality.

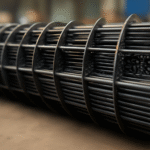

Our state-of-the-art manufacturing facility spans over 35,000 sq. ft. under crane, providing ample space for handling complex heat exchanger and pressure vessel fabrication projects. Our team comprises 150+ highly skilled experts, with a combined experience of more than 500 years and involvement in over 1,000 successful heat exchanger deliveries.

We are equipped with high-capacity machinery to handle challenging fabrication tasks:

Our comprehensive manufacturing capabilities allow us to deliver products with superior mechanical integrity, consistent quality and long operational life.

At MultiMax, we believe that manufacturing excellence comes from combining cutting-edge infrastructure with a culture of continuous improvement—ensuring every product we build meets the highest standards of quality, performance and reliability.

At MultiMax Engineering Works, quality is embedded in our DNA. Every process, product and project reflects our unwavering focus on delivering the highest standards.

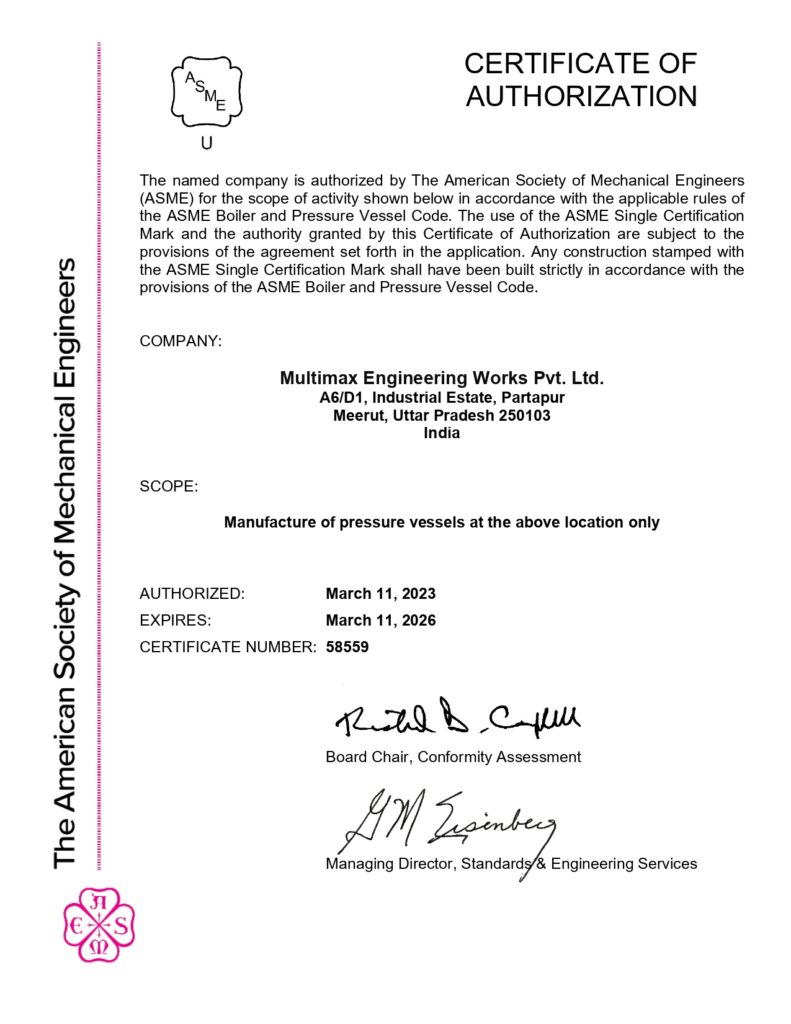

We are certified to ISO 9001 Quality Management Systems and authorized with the prestigious ASME U Stamp, enabling us to export globally. All certifications are awarded by leading industry bodies such as TÜV Nord and Lloyd’s Register, reflecting our commitment to internationally recognized standards. The company is also approved and enlisted with major EPCs such as EIL, PDIL, Technip, Toyo, etc.

Our dedicated in-house Quality Control (QC) and Quality Assurance (QA) teams play a critical role in upholding our quality benchmarks. The QA team issues Standardized Work Instructions (SWI) for shop floor operations, conducts regular audits of internal processes and sub-vendors, manages Non-Conformities (NCs) and performs Root Cause Analysis (RCA) and Corrective & Preventive Actions (CAPA).

We also prioritize Safety, Health, and Environmental (SHE) performance. Certified under ISO 14001 and ISO 45001, we go beyond compliance with frequent SHE trainings, HIRA (Hazard Identification & Risk Assessment) meetings and integrated safety protocols in all SWIs.

Ultimately, beyond certifications and audits, our product quality speaks for itself—demonstrated by our near 100% customer retention rate. A majority of our business comes from long-term repeat customers who continue to trust MultiMax for decades.

At MultiMax, quality isn’t just a certification—it’s our way of doing business.

+91 7060066048

For Marketing Enquiry +91 9456905210

For Inquiry & Info:- mktgmumbai@multimax.in

For Jobs and Careers:-hr@multimax.in

For any other Query:-info@multimax.in

A-6, I.E., Partapur, Meerut, Uttar Pradesh 250103

Copyright © 2025 Multimax. All Rights Reserved. Developed by TheTeekri Digital Marketing Company